If you are an industrial engineer working for a large retailer, you will probably spend rather a lot of time thinking about how price tags are attached to objects. These price tickets tend to start their lives at the business end of a "marking machine" a depressingly large and complex device made for the sole purpose of printing large numbers of retail tickets. Some of these devices come in the form of largish ugly rectangles that spew bundles of sticky backed tickets from rolls of ticket-making stuff the size of a car tire. Other come in the form of a gun operated by a poorly trained worker, whose barrel is a thermal printer that shoots labels at unsuspecting consumer goods. All of them are computerized, networked devices that are linked together to giant databases of barcodes and prices. However, before the era of the computer, tickets still had to be printed, and some of the pre-computer marking machines were nearly as complex as their modern day equivalents. When I was presented with the opportunity to buy an old Monarch Junior marking machine that looked like something that would be connected to the boiler of a steam locomotive, it took but a moment to separate my hard-earned money from my hard-earned person. I quickly discovered that there was no information of any kind on the net about these machines, no private collections or convenient lists of manufacture dates were to be found. Apparently marking machines, confined to the back-rooms and warehouses of the world, had been previously considered to be unworthy of documentation. This site is probably one of the few on the Internet that even acknowledges marking machines existed before 1982.

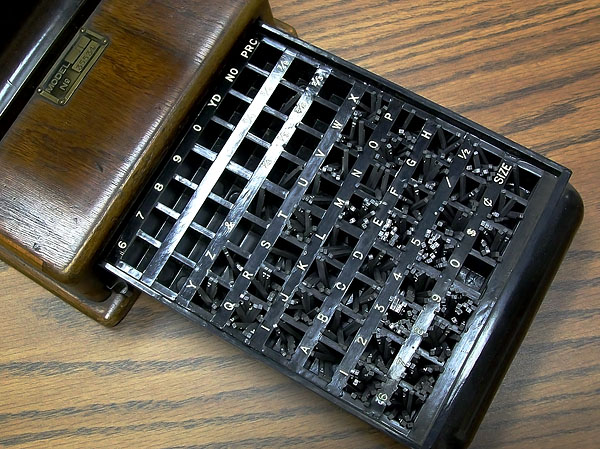

Monarch Junior Model J Marking Machine. Serial number is 10591.

I have been unable to date the machine, but if I had to guess, I would place it sometime between 1940 and 1950. Like modern marking machines it is rather large and complex for what it does. A turn of the crank will feed a ticket into the device, apply ink to the print head, advance a mechanical counter, stamp the ticket, and eject the ticket from the machine. The three digit mechanical counter is mounted to the top of the machine, it indicates how many labels have been printed. There are two levers on the top of the machine, one selects between gummed and normal ticket material, and the other lever is used to print "slip fold tickets" a type of tag that apparently did not survive the test of time. The crank, stamping arm, and all other mechanical parts of the device are made of cast metal, the base and crank handle are made of wood. I don't know what the speed specifications are on the device, but 80 labels per minute seems like a reasonable estimate for the print speed based on my own tests.

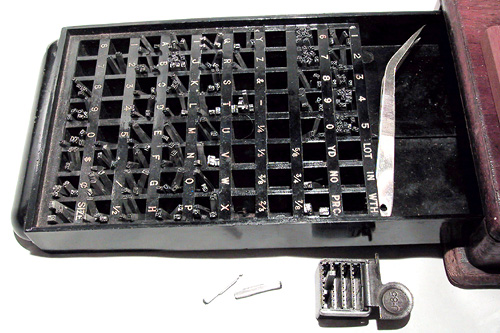

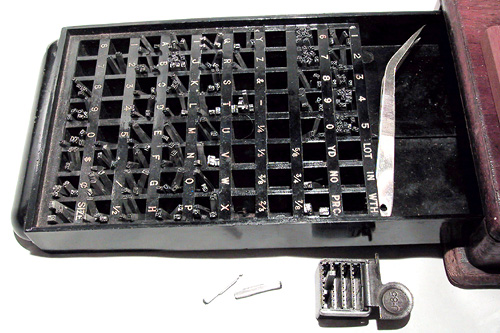

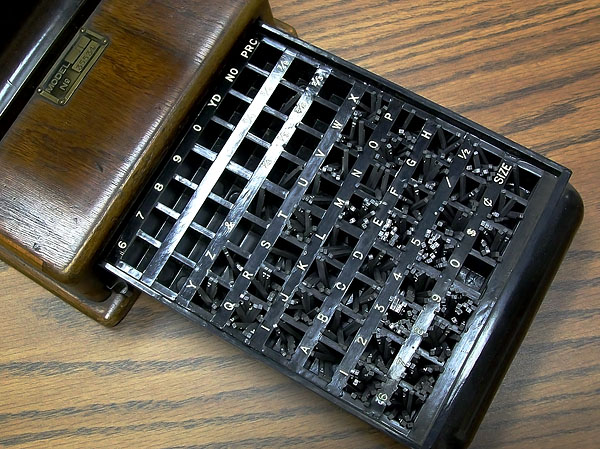

Monarch Junior Model J, stamping dies.

Of particular importance is that the machine's metal dies are still intact, as they are often missing from machines being sold at auctions and flea markets, and are critical to the device's functionality. At its heart, the Model J functions like an old fashioned printing press. A rectangular grid acts as a frame into which metal stamping dies embossed with letters and numbers can be placed, allowing the text and layout of a label to be set as needed by the user. This particular machine had a J-85 head installed, which can carry up to four ten character lines of text. A bakelite drawer in the bottom of the machine stores dies when they are not in use, this particular machine had 283 small dies in it's storage drawer, consisting of capital letters, numbers, and and many symbols and punctuation marks that would be commonly used on a retail ticket. The use of a die is a feature that means the machine can still be used today without any ill effects, metal tends to stand the test of time.

Not all mechanical marking machines are made to the rather high bar set by the Model J. I bought a Monarch 23 Dial-A-Pricer for a few dollars at a flea market in the "bad" part of town, and was not impressed. Now granted, in the city where I live there is really no "good" side of town, but varying gradients of badness can be assigned to different parts of town based on the ambient hooker / drug dealer level and frequency of carjackings. A simple measure of the badness of the neighborhood can be taken by noting that the flea market shared a building with a bona-fide porno theater, and was across the street from a place identifying itself as an "Adult Superstore". Any marking machine bought from such a locale already has at least one thing wrong with it, and for the Model 23, the seedy retail venue was only the first in a litany of problems.

Monarch 23 Dial-A-Pricer, serial number 23-96107461.

Unlike the Model J, which uses durable metal dies, the Dial-A-Pricer uses a complex mechanical print head consisting of fourteen rubber belts, arranged in two rows of seven characters. The belts are divided in half, the bottom half of each belt contains rubber dies for the digits zero through nine, as well as punctuation and common abbreviations. On the upper half of each belt is an embossed white plastic tag, which mirrors the symbol on the opposite side of the belt. Two plungers are moved through the center of the print head to select and change digits, a moving arrow will indicate which digit has been selected. The knob is turned until the white tag under the pointer displays the desired character, which causes the corresponding rubber die to be rotated into place on the underside of the print head. A largish knob at the top of the print head allows the user to set the darkness of the print transferred to the ticket.

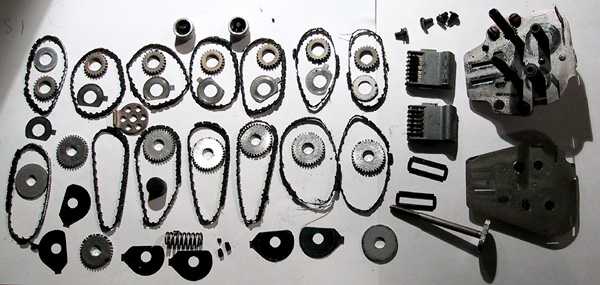

Model 23 print head, disassembled.

This design of print head is not nearly as sturdy as the all metal head used in the Model J. After thirty or more years, the ink saturated rubber has deteriorated into a sticky brew of black slime. The rubber half of the dies were in such poor shape that they could be flattened into pancakes with bare hands, and each belt had welded itself to its neighbors. The teeth on the insides of the belts that engaged the gears were rubber too, and had been cleaved off by every person who attempted to change the state of the dies before I bought the machine. I dismantled the print head into its component parts (shown above) and cleaned all the belts, but nothing could restore the state of the rubber. Best efforts could only put the machine into a cosmetically acceptable state, belts could be rotated by the knobs and the machine looks functional, but any attempt to print a label would crush the rubber portion of the print head.

Marking machines, unfortunately, are not worth very much on the collectors market. A nice older machine like the Junior Model J will fetch between $30 and $50 dollars from a collector, depending on condition and functionality. Newer machines like the Dial-A-Pricer are practically worthless, even in perfect working order. There are some notable exceptions to this however, for example, the Monarch Model JT, shown below, can fetch in excess of $400 dollars due to its extreme rarity.

Monarch Model JT jewelry marking machine.

This machine is quite rare, as it was only made for a short time during World War II. Due to the wartime metal shortage, Monarch was forced to extreme measures and designed a marking machine that was constructed almost entirely out of bakelite! Bakelite is an early brittle form of plastic, typically used for the construction of knobs and insulated terminals, and is almost never used in a high-stress mechanical device such as this. The mechanics of the Model JT function similarly to the Model J, but every part had to be redesigned to support the machine's bakelite construction.

Model JT, rear view. Note how additional stiffening braces have been incorporated into the mold to compensate for the machine's bakelite construction..

Model JT, detail of marking mechanism.

The Model JT cones equipped with the standard drawer of dies found with many old Monarch machines.

So how rare is the Model JT? So rare that the Monarch Marking company museum in Dayton Ohio does not even own an example. Unfortunately, the machine shown above is not mine, it is in the hands of a private collector who has allowed photos to be taken for this article. The machine is displayed prominently in his office, which contains many other marking machines and business collectibles. Ultimately, as it turns out, there are people who collect marking machines out there... one just has to dig very deep.